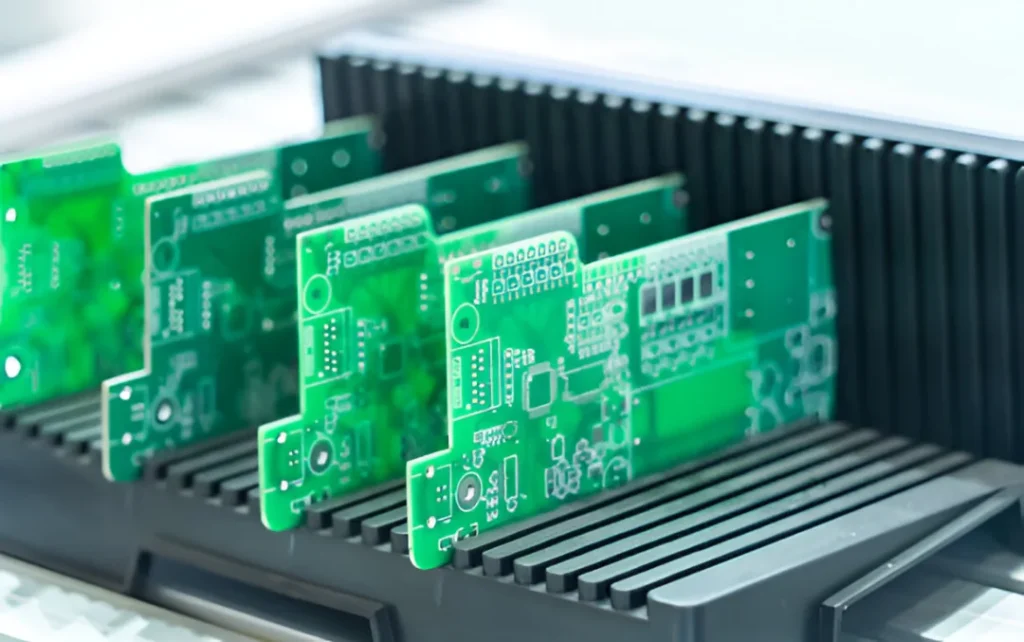

The electronics industry has entered an era where innovation, speed, and reliability define success. From everyday consumer devices to advanced industrial systems, electronic products are becoming more compact, powerful, and complex. At the heart of all these products lies a critical component that often goes unnoticed by end users: the printed circuit board (PCB).

While design and software often take the spotlight, the quality of a PCB determines how well a device performs over time. For manufacturers, selecting the right PCB supplier is not just a technical decision—it is a strategic investment that directly affects product quality, production efficiency, and brand reputation.

This article explores the growing importance of professional PCB suppliers, the challenges of modern PCB manufacturing, and why long-term supplier partnerships are essential in today’s competitive electronics market.

Why Printed Circuit Boards Matter More Than Ever

Printed circuit boards serve as the structural and electrical foundation of electronic devices. They connect components, manage electrical flow, and ensure consistent performance under varying conditions. A well-manufactured PCB supports durability, efficiency, and long-term reliability.

Modern devices demand PCBs that can handle:

- High-speed signal transmission

- Compact and dense component layouts

- Thermal stress and heat dissipation

- Long operational lifecycles

As devices shrink in size and increase in functionality, PCB requirements become more demanding. Even minor manufacturing flaws can lead to product malfunctions, system failures, or costly recalls.

The Evolution of PCB Manufacturing

PCB manufacturing has evolved significantly over the past decade. Earlier, simple single-layer boards were sufficient for most applications. Today, manufacturers frequently require:

- Multi-layer PCB structures

- High-density interconnect designs

- Fine-pitch and micro-component support

- Specialized materials for high-frequency or high-temperature use

These advancements require suppliers to invest in advanced equipment, skilled engineering teams, and strict quality control systems. PCB manufacturing is no longer just about production—it is about precision engineering.

What Makes a PCB Supplier Truly Reliable?

Not all PCB suppliers are equipped to handle modern manufacturing challenges. A reliable supplier stands out through experience, systems, and commitment to quality.

Technical Expertise

An experienced supplier understands PCB design principles, material selection, and performance requirements. This expertise allows them to support complex designs and reduce manufacturing risks.

Quality Control Standards

Consistent quality depends on thorough inspection processes, including electrical testing and visual checks. Reliable suppliers ensure that every board meets defined specifications before delivery.

Production Stability

Manufacturers need predictable results. A dependable supplier maintains consistency across production batches, whether delivering prototypes or large-scale orders.

Communication and Transparency

Clear communication helps align expectations, timelines, and technical requirements. This reduces delays and ensures smoother collaboration.

Global PCB Suppliers and Manufacturing Efficiency

As electronics companies expand into international markets, global PCB suppliers play a crucial role in maintaining efficiency. Their ability to manage supply chains, scale production, and maintain standardized processes helps manufacturers meet market demands without compromising quality.

Global suppliers offer advantages such as:

- Faster production turnaround

- Cost-efficient manufacturing solutions

- Scalable output for growing demand

- Stable long-term supply relationships

These benefits are particularly valuable for companies operating in competitive, time-sensitive markets.

PCB Suppliers as Brand Partners

Although end users rarely see the PCB inside a product, its quality directly influences user experience. Reliable devices build trust, while repeated failures damage brand credibility.

For this reason, many manufacturers view PCB suppliers as an extension of their brand. A high-quality board reflects careful engineering, attention to detail, and professional standards—qualities that customers associate with trusted products.

This is why many electronics manufacturers choose to work with established partners like GlobalWell Printed Circuit Board Supplier when consistency, precision, and manufacturing reliability are essential.

Reducing Manufacturing Risks Through Experience

Production risks increase significantly when working with inexperienced suppliers. Common issues include inconsistent output, delayed timelines, and miscommunication between design and manufacturing teams.

Experienced PCB suppliers help mitigate these risks by:

- Identifying design-for-manufacturing issues early

- Offering practical engineering feedback

- Maintaining stable and repeatable production processes

- Ensuring on-time delivery

This proactive approach saves time, reduces costs, and improves overall product reliability.

Supporting Multiple Industries with Precision Manufacturing

Modern PCB suppliers often serve a wide range of industries, including consumer electronics, industrial automation, telecommunications, and specialized equipment manufacturing. Each industry has unique performance and compliance requirements.

Suppliers with cross-industry experience understand how to adapt PCB designs, materials, and processes to meet different operational demands. This flexibility makes them valuable long-term partners rather than one-time vendors.

Long-Term Partnerships Over Short-Term Solutions

Successful electronics manufacturers focus on building long-term relationships with their suppliers. These partnerships foster trust, improve collaboration, and lead to continuous improvement over time.

Long-term supplier relationships offer benefits such as:

- Improved production planning

- Better cost predictability

- Faster development cycles

- Consistent quality across product lines

Such collaboration is essential for companies aiming to scale sustainably in competitive markets.

Choosing the Right PCB Supplier for Future Growth

As technology continues to advance, PCB manufacturing will become even more complex. Suppliers that invest in innovation, quality systems, and skilled teams will play a critical role in shaping the future of electronics.

Manufacturers evaluating potential partners should look beyond price and focus on value—technical capability, quality assurance, communication, and long-term support. Working with experienced providers like GlobalWell Printed Circuit Board Supplier allows businesses to innovate with confidence while maintaining high manufacturing standards.

A Trusted Manufacturing Presence

In today’s competitive electronics landscape, manufacturers increasingly rely on professional PCB partners with a strong global presence. Platforms such as globalwellpcba.com reflect how modern suppliers present their capabilities, standards, and manufacturing expertise to international clients.

A strong digital presence combined with proven manufacturing processes helps build confidence among businesses seeking reliable PCB solutions.

Conclusion

Printed circuit boards may operate behind the scenes, but their impact on modern electronics is undeniable. From product performance and durability to brand trust and customer satisfaction, the role of a PCB supplier is central to success.

By partnering with experienced, quality-focused PCB manufacturers, electronics companies position themselves for long-term growth in an increasingly demanding industry. Choosing the right supplier today ensures a stronger, more reliable foundation for tomorrow’s innovations.