High-efficiency particulate air systems play a critical role in environments where air quality directly affects safety, research integrity, or production outcomes. From cleanrooms and laboratories to healthcare and manufacturing facilities, HEPA filtration systems are relied upon to capture airborne particles and maintain controlled conditions. The HEPA testing process exists to verify that these systems perform as intended under real operating conditions, mentions Keyrenter Silicon Valley Management. Rather than being a one-time verification, testing is an ongoing practice that confirms airflow integrity, filter installation, and system response. Understanding how the HEPA testing process works clarifies why consistent evaluation is essential for maintaining controlled environments and preventing unseen risks.

Understanding HEPA system verification

Purpose and Scope of HEPA Testing

The HEPA testing process is designed to confirm that filtration systems are functioning correctly and that no unfiltered air bypasses the filter media. Testing focuses not only on the filter itself but also on the surrounding housing, seals, and airflow pathways. Even a properly manufactured filter can fail to perform if installed incorrectly or if gaps compromise its performance. HEPA testing evaluates the entire assembly as a working unit rather than treating components in isolation. Organizations that start your HEPA testing process often do so to establish confidence that their controlled environment meets defined performance requirements. This scope ensures that air cleanliness is verified where it matters most: at the point of use, not on paper alone.

Preparation Before Testing Begins

Before any HEPA testing is performed, careful preparation takes place. Testing professionals review system design, airflow specifications, and operational requirements to understand how the system is intended to perform. Equipment such as aerosol generators and particle counters must be calibrated and positioned correctly to avoid misleading results. Environmental conditions are also considered, as airflow patterns and pressure differentials can influence readings. Preparation ensures that testing reflects actual operating conditions rather than artificial scenarios. This groundwork reduces the likelihood of false failures or overlooked issues and supports accurate interpretation of results.

A Short Look at Testing Precision

Precision is central to the HEPA testing process. Small variations in particle counts can indicate significant performance differences. Accurate testing depends on controlled aerosol introduction and consistent measurement techniques. Precision ensures that results reflect real system behavior rather than testing inconsistencies. Reliable precision supports meaningful conclusions.

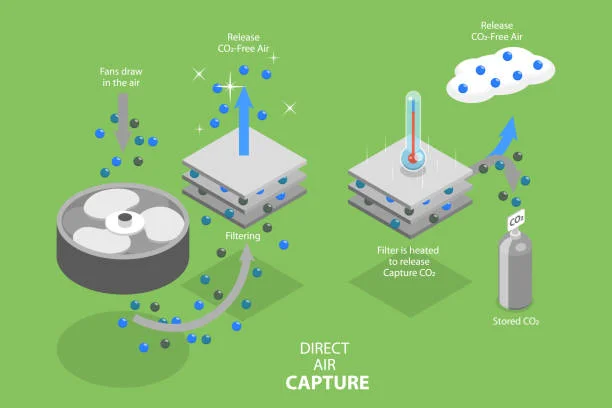

Aerosol Challenge and Detection Methods

A core component of HEPA testing involves introducing a controlled aerosol upstream of the filter and measuring particle penetration downstream. This aerosol challenge simulates airborne contaminants that the filter is designed to capture. Detection instruments scan the downstream area to detect any particle leakage exceeding acceptable thresholds. This process reveals whether the filter media and seals are working together effectively. The method is sensitive enough to detect even minor leaks that would otherwise go unnoticed. By visualizing how particles behave under controlled conditions, testing provides direct evidence of system integrity.

Evaluating Filter Installation and Sealing

HEPA filters rely heavily on proper installation to function correctly. Testing often uncovers issues related to gasket compression, frame alignment, or housing deformation. Even small installation errors can allow unfiltered air to bypass the filter entirely. The HEPA testing process evaluates these factors by identifying localized leakage patterns. When leaks are detected, their location helps pinpoint whether the issue lies with the filter media, seal, or housing. This evaluation ensures that corrective actions address root causes rather than symptoms. Proper sealing supports consistent filtration performance over time.

Interpreting Test Results Accurately

Test results must be interpreted within the context of system design and operational requirements. Not all detected particles indicate failure; acceptable limits are defined by standards and the intended use. Testing professionals analyze data trends, leak locations, and airflow behavior to determine whether performance meets criteria. Interpretation requires understanding both the testing method and the system being evaluated. Accurate interpretation prevents unnecessary interventions while ensuring genuine issues are addressed. This balance supports both safety and efficiency in controlled environments.

Impact of Airflow Patterns on Test Outcomes

Airflow behavior significantly influences HEPA test results. Turbulence, velocity changes, and pressure differentials can affect how aerosols move through the system. Testing accounts for these patterns by adjusting probe movement and scan techniques. Understanding airflow dynamics helps distinguish true leakage from particle redistribution caused by airflow. This awareness ensures that results reflect filter performance rather than airflow anomalies. Evaluating airflow alongside filtration reinforces the reliability of the testing process.

Routine Testing and Long-Term Performance

HEPA testing is not limited to initial installation. Routine testing confirms that filters continue to perform as systems age and operating conditions change. Over time, vibration, thermal cycling, or maintenance activities can affect seals and housings. Periodic testing identifies these changes before they compromise air quality. Long-term performance monitoring supports consistent environmental control and reduces the risk of unexpected failures. Routine testing becomes part of a preventive approach rather than a reactive response to problems.

Documentation and Compliance Considerations

Documentation is an essential outcome of the HEPA testing process. Test reports document the methods used, the results obtained, and any corrective actions taken. These records support internal quality systems and external compliance requirements. Clear documentation ensures traceability and accountability, allowing organizations to demonstrate that air quality controls have been verified. Documentation also provides historical context for future testing, helping identify trends or recurring issues. Maintaining accurate records strengthens confidence in controlled environment management.

Coordination With Facility Operations

HEPA testing often requires coordination with facility operations to minimize disruption. Testing schedules are planned to align with production cycles, maintenance windows, or occupancy considerations. Effective coordination ensures that testing does not interfere with critical activities while still reflecting real operating conditions. Communication between testing personnel and facility staff supports smooth execution. This collaboration ensures that testing integrates seamlessly into broader operational workflows.

Adapting Testing to Different Environments

Different environments impose unique demands on HEPA testing. Cleanrooms, healthcare facilities, and manufacturing spaces each have distinct airflow designs and performance criteria. The testing process adapts to these differences by adjusting methods and acceptance thresholds. Tailoring testing to the environment ensures relevance and accuracy. This adaptability allows HEPA testing to remain effective across diverse applications without compromising reliability.

The HEPA testing process plays a vital role in verifying the integrity of air filtration systems used in controlled environments. Through careful preparation, aerosol challenge methods, airflow evaluation, and accurate interpretation, testing confirms that filters and housings perform as intended. Routine testing and thorough documentation support long-term performance and compliance. Understanding how HEPA testing works highlights why it is an essential practice rather than a procedural formality. By validating airflow integrity and filtration effectiveness, HEPA testing helps maintain environments where air quality is critical to safety, accuracy, and operational success.