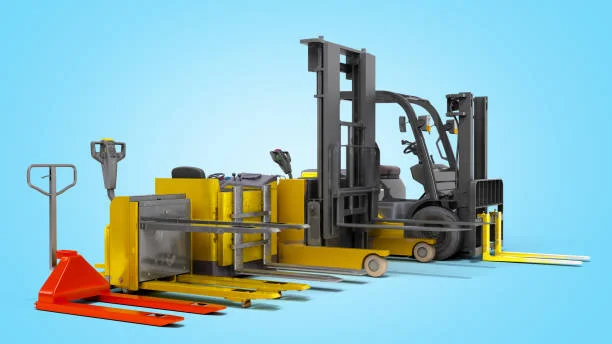

Forklifts are essential machines in warehouses, manufacturing facilities, and distribution centers, serving as the backbone for material handling and logistics operations. Their efficiency, safety, and longevity depend heavily on the quality and maintenance of their components of High-Quality Forklift parts. Forklift parts are not just simple mechanical components; they play a critical role in ensuring that these machines operate smoothly and reliably, supporting the vast array of tasks they are designed to perform. Understanding the various types of forklift parts, their functions, and maintenance requirements is key to maximizing productivity and minimizing downtime.

Forklifts are complex machines that integrate multiple systems, each requiring specialized parts for proper functionality. From the engine and transmission to hydraulic systems and lifting mechanisms, every part must be carefully selected and maintained. One of the most important aspects of forklift operation is knowing how these components work together. For example, the hydraulic system relies on cylinders, pumps, and valves to lift and lower loads efficiently, while the transmission system ensures smooth and precise control of speed and direction. Neglecting any of these systems can lead to mechanical failures and reduced efficiency, highlighting the importance of using reliable forklift parts or High-Quality Forklift parts.

Stay ahead of the curve—related posts designed to inspire and inform!

Key Components of Forklift Machinery

Forklifts consist of numerous essential components, each with a specific role in ensuring safe and effective operation. Some of the most critical forklift parts include:

- Engine and Powertrain Components: These are the heart of the forklift. Engines can be powered by diesel, gasoline, or electricity. The powertrain, which includes the transmission, differential, and drive axle, ensures that energy from the engine is effectively transferred to the wheels, enabling movement and load handling.

- Hydraulic System Components: Hydraulic systems are responsible for lifting and lowering loads. Key components include hydraulic pumps, cylinders, hoses, and valves. Proper maintenance of these parts is crucial because any failure can result in unsafe lifting conditions or equipment breakdowns.

- Mast and Carriage Components: The mast is the vertical assembly that raises and lowers the forks. It includes rollers, chains, and the carriage, which holds the forks. These forklift parts or High-Quality Forklift parts must be robust and well-maintained to handle heavy loads safely.

- Forks: Forks are among the most visible parts of a forklift, and their strength is critical to the safe handling of materials. They must be inspected regularly for cracks, bends, or wear.

- Braking System Components: Brakes are vital for safety, and the system includes drums, discs, calipers, and hydraulic components. Any malfunction in the braking system can lead to accidents or serious injuries, making regular checks and replacement of worn parts essential.

- Electrical System Components: Modern forklifts incorporate electrical systems for ignition, lighting, and electronic controls. Batteries, starters, alternators, and wiring are all integral forklift parts that require regular inspection to prevent unexpected failures.

- Tires and Wheels: Tires affect stability and traction. Solid, pneumatic, and cushion tires are available, each suited for specific operational environments. Forklift parts or High-Quality Forklift parts like wheels and axles must be maintained to ensure safe operation and avoid damage to goods and flooring.

The Importance of Quality Forklift Parts

Investing in high-quality forklift parts is essential for several reasons. Low-quality or incompatible parts can lead to frequent breakdowns, increased maintenance costs, and safety hazards. Reliable parts ensure smoother operation, enhance fuel efficiency, reduce downtime, and extend the lifespan of the forklift. Businesses that prioritize quality parts experience fewer interruptions in operations and lower overall maintenance expenses, ultimately improving productivity and profitability.

Maintenance Practices for Forklift Parts

Regular maintenance of forklift parts is essential to prevent costly repairs and ensure worker safety. Maintenance routines should include:

- Routine Inspections: Daily or weekly inspections can identify worn-out or damaged parts before they fail. This includes checking hydraulic hoses, tires, brakes, and forks for wear or cracks.

- Lubrication: Proper lubrication of moving parts such as chains, rollers, and bearings reduces friction and prevents premature wear.

- Cleaning: Dust, dirt, and debris can accumulate and affect the performance of hydraulic and electrical components. Regular cleaning helps maintain efficiency.

- Scheduled Replacements: Some parts, such as filters, tires, and brake pads, have predictable lifespans. Replacing these components on schedule prevents unexpected downtime.

Maintenance is not just about avoiding breakdowns; it also contributes to workplace safety. Faulty forklift parts or High-Quality Forklift parts can cause accidents, product damage, and injuries, making adherence to manufacturer recommendations for inspection and maintenance a priority.

Choosing the Right Forklift Parts

Selecting the correct forklift parts is as important as maintaining them. Consider the following factors when sourcing parts:

- Compatibility: Ensure the parts are compatible with the specific make and model of the forklift. Using incompatible parts can cause mechanical failures.

- Durability: Choose parts made from high-quality materials that can withstand the operational demands of your facility.

- Supplier Reputation: Working with reputable suppliers ensures access to genuine parts, technical support, and warranty coverage.

- Cost vs. Longevity: While cheaper parts may seem economical initially, investing in durable parts can save money in the long run by reducing downtime and replacement frequency.

Technological Advancements in Forklift Parts

The forklift industry has embraced technological advancements to enhance efficiency, safety, and sustainability. Modern forklifts now feature electronic control systems, sensors, and automation components. These advancements require specialized forklift parts or High-Quality Forklift parts, such as electronic control modules, proximity sensors, and advanced hydraulic components. Understanding these innovations and integrating them into maintenance and replacement strategies is crucial for modern material handling operations.

For example, electric forklifts rely heavily on battery technology, including battery cells, chargers, and monitoring systems. High-quality battery components ensure longer operational hours and reduce energy costs. Similarly, sensors and automation components improve precision and reduce human error, further emphasizing the need for reliable parts in technologically advanced forklifts.

The Role of Forklift Parts in Safety

Safety is a fundamental concern in material handling operations. Malfunctioning forklift parts can result in accidents that cause injuries or damage to property. For example, worn forks may bend or break under load, hydraulic leaks can lead to sudden drops, and defective brakes can cause collisions. Ensuring that all parts are regularly inspected, maintained, and replaced when necessary is critical for creating a safe working environment. Comprehensive safety training should also emphasize the importance of proper forklift part maintenance and adherence to operational guidelines.

Environmental Considerations

Modern businesses are increasingly focused on sustainability and environmental impact. Using high-quality forklift parts contributes to eco-friendly practices by improving fuel efficiency, reducing emissions, and minimizing waste from frequent part replacements. Electric forklifts, in particular, benefit from efficient battery components and energy recovery systems, reducing the environmental footprint of material handling operations. Choosing environmentally friendly forklift parts or High-Quality Forklift parts aligns with corporate sustainability goals and regulatory compliance.

Conclusion

Forklifts are indispensable in modern logistics and manufacturing, but their effectiveness hinges on the performance of their components. Investing in high-quality forklift parts, understanding their functions, performing regular maintenance, and choosing the right replacements are all critical steps in ensuring operational efficiency, safety, and longevity. Businesses that prioritize the careful selection and maintenance of forklift parts or High-Quality Forklift parts not only improve productivity but also protect their workforce and optimize operational costs. Ultimately, the thoughtful management of forklift parts transforms forklifts from mere machinery into reliable, long-lasting assets that drive the success of any material handling operation.

Endless insights await—explore more content at The Tipsy Gypsies that keeps you informed!